![]()

Many brand owners, when dealing with Knitwear for the first time, are surprised by its complexity. Unlike Woven fabrics, where “what you cut is what you get,” knitwear is more like an organic process of “growing from nothing.”

In the world of custom manufacturing at Lewen Garment, we aren’t just making clothes; we are executing a precise piece of “Code Engineering” for you. To ensure your product achieves the ideal texture and fit, here is the complete “Evolutionary Theory” of our collaboration.

Phase 1: The Blueprint (Inspiration & Requirements)

This step is the cornerstone of the project. The texture of the sweater determines its soul, while the design sketch determines its skeleton.

Collaboration Checklist:

- [You]: Provide design sketches and Reference Samples. Most importantly, define the texture: Do you want the soft, waxy feel of cashmere, or the crisp, dry touch of a cotton blend?

- [Lewen]: We perform a design task analysis. We discuss the silhouette and structure in 2D space and provide professional yarn suggestions.

Phase 2: Source Code Initialization (Sourcing & Costing)

Choosing the right yarn is half the battle. Different yarn counts and compositions directly affect the cost and the final look.

Collaboration Checklist:

- [You]: Select your desired colors based on the color cards we provide.

- [Lewen]: We source raw materials and perform strict Cost Accounting. We test the basic performance of the material to ensure the yarn count and composition meet the design requirements.

Phase 3: Programming & Beta Test (The Core Stage)

This is the most mysterious and technical part of knitwear. We often say: “Wovens rely on cutting; Knits rely on calculation.”

Collaboration Checklist:

- [You]: (Resting Phase) You just need to wait backstage for the birth of the Proto Sample.

- [Lewen]:

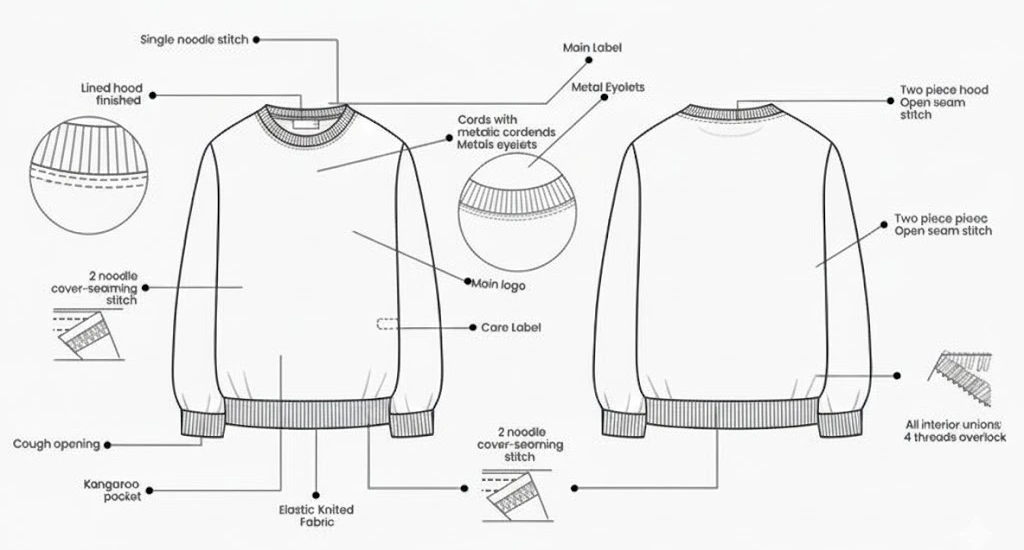

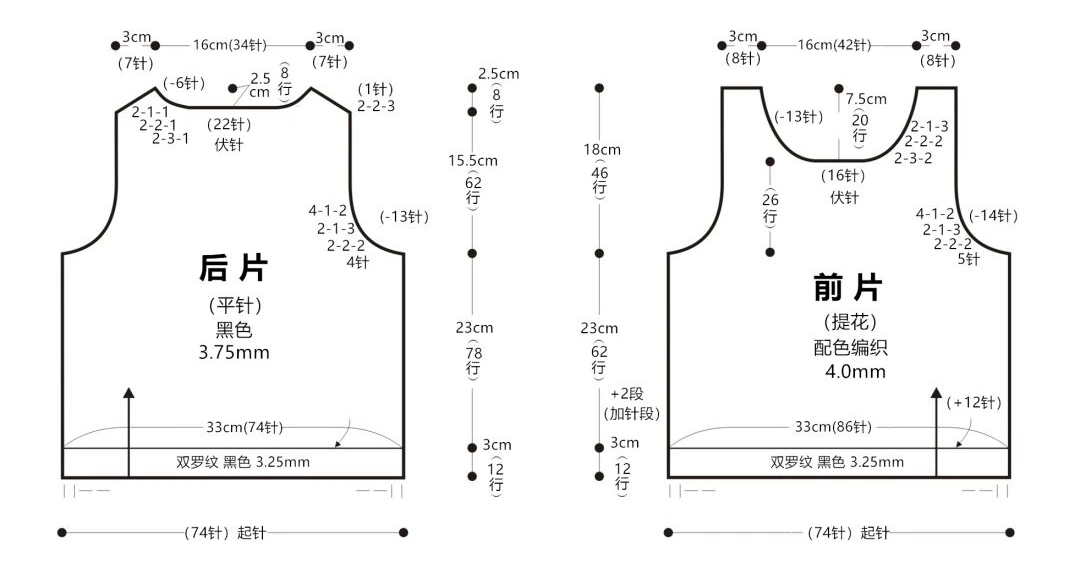

1. Calculations : The master technician formulates specific specs (chest, length, etc.) based on the design. This is the foundation of the pattern.

2. Pattern Programming : Translating the pattern into machine-readable code (Digital Pattern Programming).

3. Proto Sampling : Producing the first sample. This is crucial to test the Natural Shrinkage Rate of the yarn, ensuring precise dimensions for bulk production.

Phase 4: Debugging (Correction & Iteration)

Once the sample is out, we need to “Find Bugs” together.

Collaboration Checklist:

- [You]: Try it on yourself or use a fit model. Check if the hand-feel, color, measurements, and fit meet your expectations.

- [Lewen]: We collect your feedback for defect analysis (e.g., Is the collar lying flat? Is the sleeve cap ease even?). Based on this, we modify the Calculation Sheet, essentially “optimizing the code.”

Phase 5: Compilation & Execution (Production Launch)

Once confirmed, we hit the “Start” button, and bulk production begins.

Collaboration Checklist:

- [You]: Confirm the Pre-production Sample (PPS) and issue the bulk production order.

- [Lewen]:

1. Knitting Panels: Computerized flat knitting machines knit the fabric panels. The beauty of knitwear lies in “Widening, Narrowing, and Binding off” stitches to form the shape directly, meaning less waste and smoother lines compared to cutting.

2. Secondary Crafts: If there is embroidery or printing, we handle it on the panels before assembly to ensure the pattern doesn’t deform.

Phase 6: Assembly (Linking)

Unlike standard sewing machines, knitwear factories use “Linking Machines.”

Collaboration Checklist:

- [You]: Await the final product.

- [Lewen]: Workers use the linking machine to join the garment panels “Loop by Loop.” This specific connection method ensures the seams have excellent elasticity and stretch, so they don’t feel tight or restrictive when worn.

Phase 7: UI/UX Polish (Finishing & Ironing)

This is the key step that determines the “Premium Feel.” A sweater fresh off the machine is raw and stiff; it must go through this “Soul Injection.”

Collaboration Checklist:

- [You]: Prepare your warehouse for receiving.

- [Lewen]:

1. Washing: This isn’t just cleaning; it’s about stabilizing dimensions and controlling the “blooming” of the yarn (how fuzzy it gets) to achieve that desired “soft & waxy” hand-feel.

2. Ironing/Steaming: The ironing department shapes the garment. We steam the panels into their specified 3D form, ensuring a flat appearance and natural drape.

Phase 8: Final Release (QA & Delivery)

Collaboration Checklist:

- [You]: Receive goods and prepare for launch.

- [Lewen]: Final QA Inspection. We check for broken yarns, dropped stitches, loose threads, or size deviations. Only products that are 100% up to standard are packed and shipped.

💡 Summary: Why is Making a Sweater Like “Writing Code”?

Producing a custom sweater is like “writing a piece of self-growing code” on a computer:

- Calculations & Programming = Source Code: Determines the basic logic of the program.

- Yarn = Variables: Since yarn is elastic (like variables in code), we must control it precisely.

- Proto Sample = Beta Version: Run the program once to see if there are any bugs.

- Washing Test = Debugging: Fixing dimensional deviations by testing shrinkage rates.

- Ironing/Shaping = GUI Design (User Interface): Giving the code a beautiful “interface” so the user finds it comfortable and easy to use.

When every byte (every yarn) is accurate, the final result presented to you is a perfectly running “Program” (The Finished Garment).

Ready to start your “Coding” journey? Contact Lewen Garment, and let’s “compile” your design inspiration into tangible reality.